This page will be greatly expanded once I have better access to pictures and videos of my creations in action.

Smelter build and use, 3d printed air turbine project,

Long-board builds

Just some pictures and descriptions of my long-board builds along with some problems I faced and how I solved them.

Start, the build starts with 1/8 inch Baltic birch plywood that I had to source from a local specialty supplier as the big box stores in my area don’t sell real Baltic birch and therefore it would not hold up as well over time.

Once I got my sheets I had to decide how I wanted to cut them, I decided to cut them at 1 foot increments to leave extra space for imperfections or mistakes. As a board is rarely over 4 feet long I decided to get an extra strip from the 5*5 sheets and cut the 1 foot off the top. I had to also pay attention to the direction of the strands of wood in the plywood as these sheets are very flexible on one axis and stiff on the other. With two sheets I had to be careful to cut them opposite in order to an even amount of each direction.

The next problem would be defining and holding the shape of the board that I wanted. For that I would need a press and a large number of clamps.

While the press isn’t the most beautiful thing in the world, it is functional and very cheap. Being the cacophony of scrap wood that it is, it was practically free and can put out some surprising shapes with the right adjustments.

After testing the fit and end shape, all one has to do is layer the wood in the correct order with glue in between, each board uses about 4-6 sheets depending on the flexibility and length desired.

This is the first board that I was able to make, I stained and sealed the board with spar urethane. I added the handles to help with travel.

My second board is one that was made for longer rides and an angled deck. I achieved this in the end by modifying the press which gave me the right angle for a single drop down mount that allows for larger wheels which give a much smoother ride.

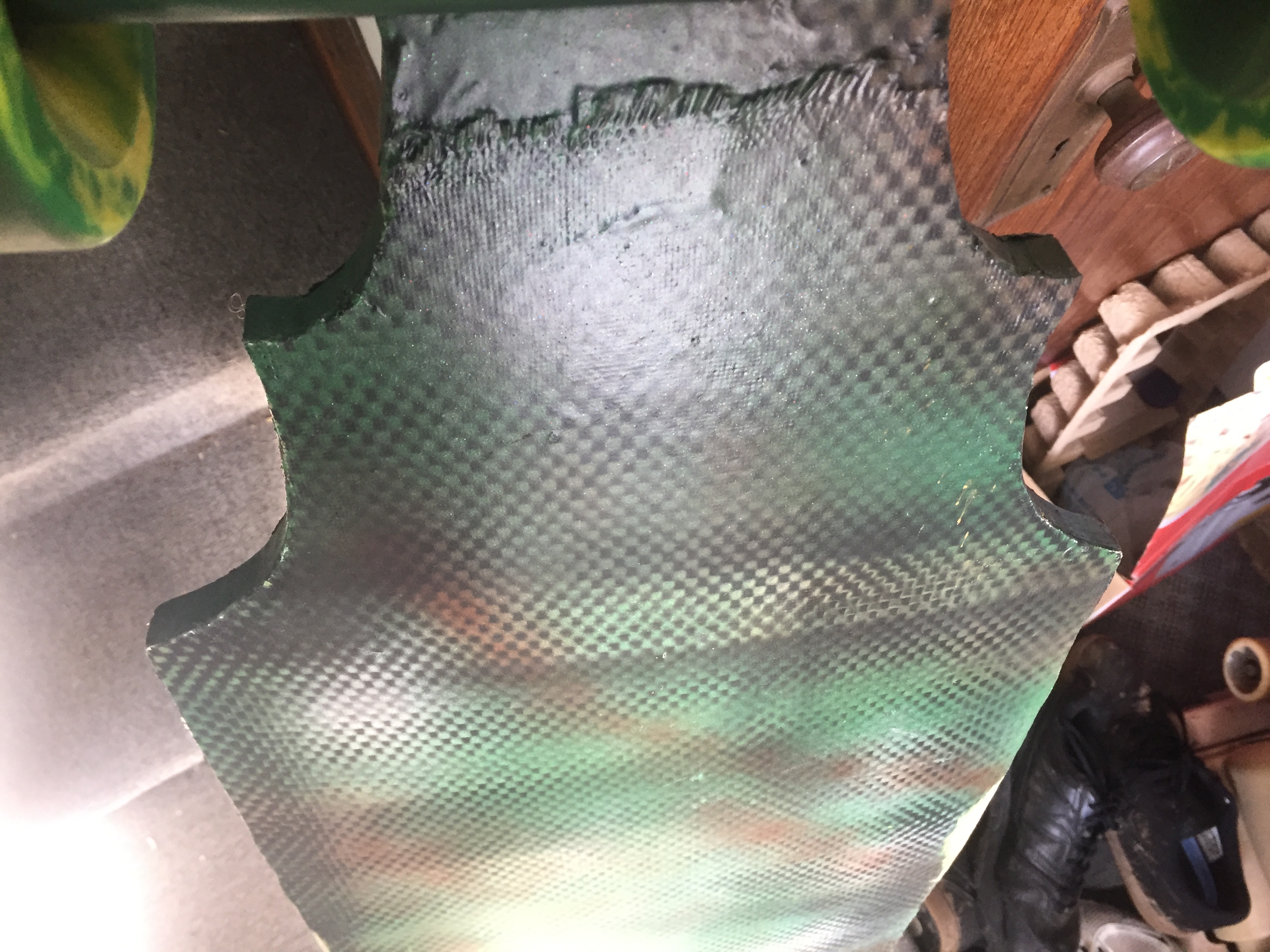

After testing my second board I realized that it would require a much stiffer deck in order to avoid bottoming out. To strengthen the deck I “glassed” the bottom of the deck using a fiberglass weave and epoxy resin.

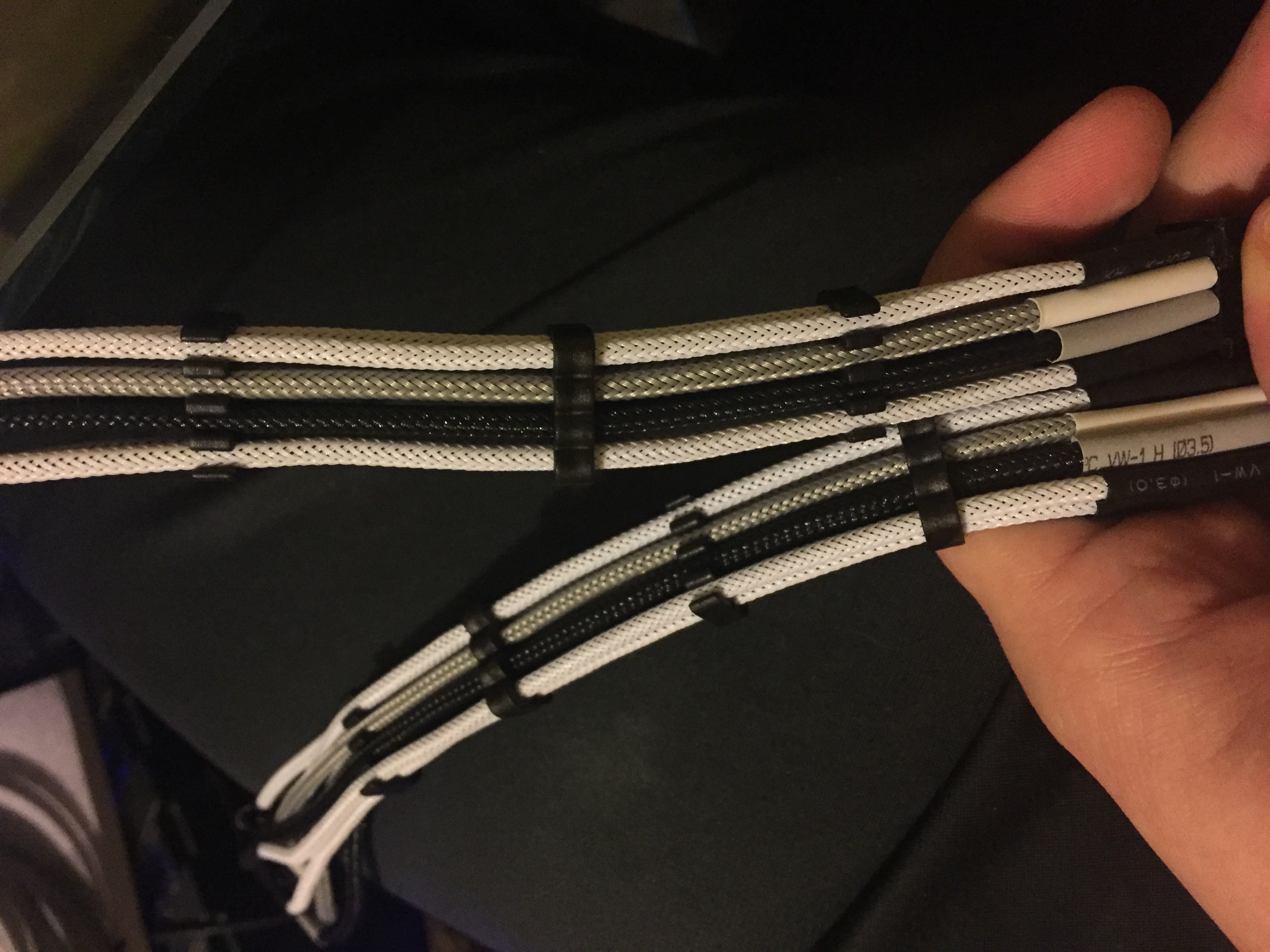

Custom Cable Sleeving

Headphone Stand

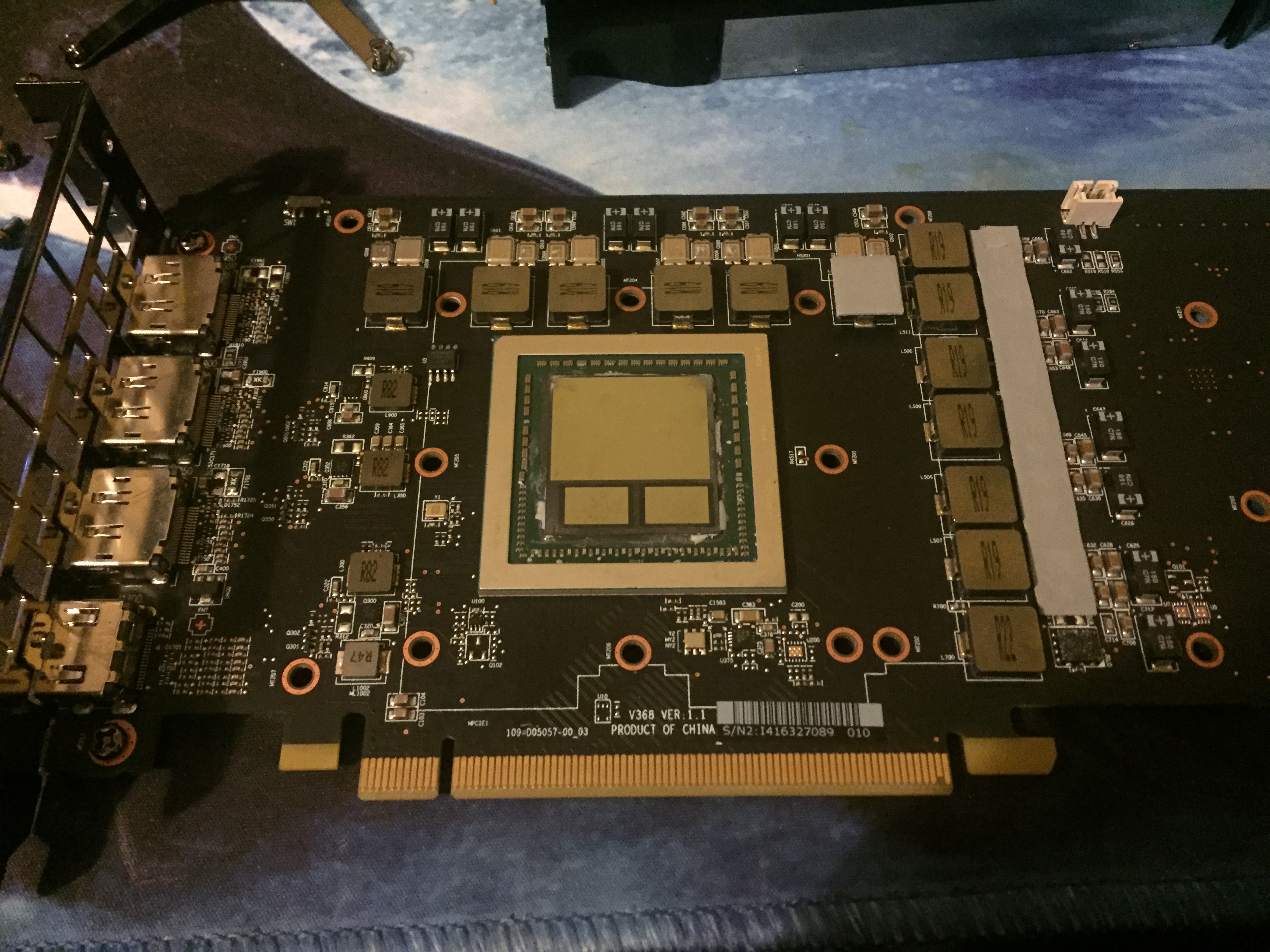

Current build: Graphics card cooler

In my project of switching my new computer to water cooling, I will need a water block for my GPU. While the CPU one was about $13, a GPU block goes anywhere from $100-250. So in order to dramatically save the total cost from doubling, I’m attempting to combine skills and equipment from multiple current classes. Through these classes and free time spent on this project I’m going to make a 3D model in CAD software of the metal section of my part. I will use this printed model to dip in a slurry for an investment casting of the cooler. This will make a very fine detail casting that I can use which will hold most marks made from the printing, any detail not usable on the casting will be machined out using a CNC machine.

Food pic collection.

While its not as technical I do also enjoy making various dishes and expanding my horizon by challenging myself to make more complicated or unusual things.

Sushi

Sushi is one of my latest dishes that I’ve been attempting. Between choosing ingredients to mix to making sure the rice is seasoned and cooked perfectly, its and all around fun dish for me to make.

French Onion/zwiebel soup

This soup is one of the first dishes from a restaurant that I enjoyed so much I decided to make it at home from scratch. From making the bone beef broth to the garlic bread croutons, this dish can be as simple or as complicated as one wants, but it can also turn out perfect.